Select equipment

Data sheets of pressure-reducing desuperheating station, of stop valves, of regulating valves

- Stop Valve

- Gate Valve (Medium Parameters) 2c,1511, 1533, 1126, 1016

- Gate Valve (High Pressure) 1120, 1123, 1156, 1012, 1013, 1015, 880, 881, 882, 883, 884,885, 887

- Check Valve

- Steam Trap

- Safety Valve 7с

- Pulse Valve 8с

- Pulse Valve 112

- Main Safety Valve

- Pulse Valve 586

- Regulating disk valve

- Regulating Rotary Valve 6c

- Regulating Needle Valve with lever actuation

- Regulating Needle Valve 10c and other

- Throttle Control Valve

- Quick-Release Valve

- Butterfly Valve

- Double-Seat Regulating Valve 14с

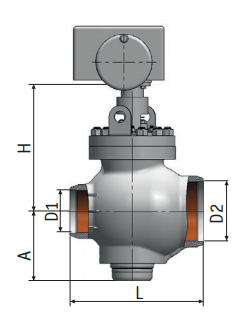

6с-13-5Э

| Destignation | Dn, mm | Pn, MPa | Kvy, |

F, cm2 | Torque, N•m | D1, mm | D2, mm | L, mm | H, mm | A, mm | Actuator type*** | Weight, kg | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 250 | 10,0 | 450 | 370 | 147 | 67 | 254 | 303 | 600 | 490 | 272 | МЭОФ 250/25-0,25У-99К | 260,7** |

Convention

body – steel 20ГСЛ (GOST 108.961.003);

cover – steel 20 (GOST 1050);

valve seat, bonnet, spindle – steel 20 (GOST 1050) with catalytic nitrogenization.

Regulating rotary valves are manufactured in accordance with Technical Specification 3742-002-79315310-2007.

Rotary valves are used for regulating pressure or discharge of working medium. Flow of working medium is regulated by changing flow area by means of rotating valve spindle against the valve seat. These valves are not used as stop valves. Connection to pipeline – by welding. Operation – automatic control by means of remote or built-in electric drive.

** without electric actuator