Select equipment

Data sheets of pressure-reducing desuperheating station, of stop valves, of regulating valves

- Stop Valve

- Gate Valve (Medium Parameters) 2c,1511, 1533, 1126, 1016

- Gate Valve (High Pressure) 1120, 1123, 1156, 1012, 1013, 1015, 880, 881, 882, 883, 884,885, 887

- Check Valve

- Steam Trap

- Safety Valve 7с

- Pulse Valve 8с

- Pulse Valve 112

- Main Safety Valve

- Pulse Valve 586

- Regulating disk valve

- Regulating Rotary Valve 6c

- Regulating Needle Valve with lever actuation

- Regulating Needle Valve 10c and other

- Throttle Control Valve

- Quick-Release Valve

- Butterfly Valve

- Double-Seat Regulating Valve 14с

1с-13-1

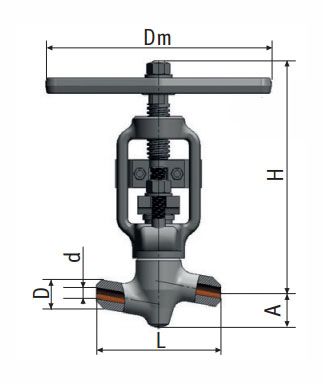

| Destignation | Dn, mm | Pn, MPa | ξ | Torque, N•m | n | D, mm | d, mm | L, mm | A, mm | H, mm | DM, mm | Actuator type*** | Weight, kg | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 50,0 | 560 | 3,8 | 25 | 3,8 | 22 | 10 | 110 | 28 | 204 | 150 | 3,0 |

Convention

body – steel 12Х1МФ (GOST 8479);

yoke – steel 20, steel 25 (GOST 8479);

valve stem – steel 12Х18Н10Т (GOST 5949) with catalytic nitrogenization;

valve spindle – steel 20Х13 (GOST 5949);

valve seat – steel 12Х18Н10Т (GOST 5949) with catalytic nitrogenization or building-up welding 04Х19Н9С2.

Stop valves are manufactured in accordance with Technical Specification 3742-002-79315310-2007.

Stop valves are used for complete cutting off (opening) steam or water flow. These valves are used on horizontal or vertical pipelines. Connection to pipeline – by welding.

* working pressure, Рр ** without electric actuator *** ref. electric drives section