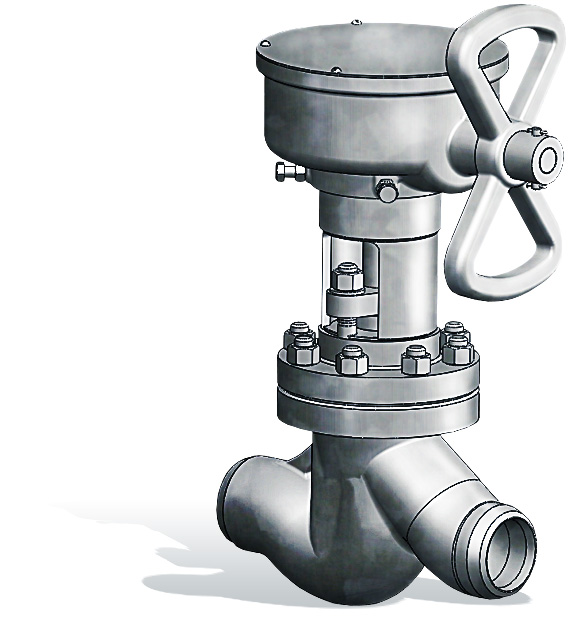

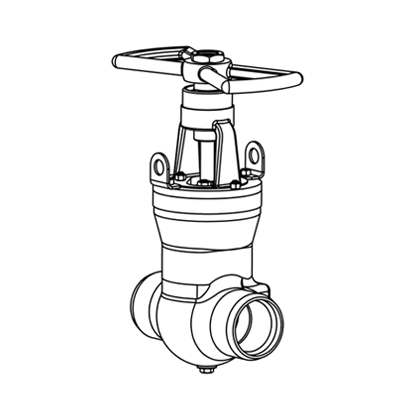

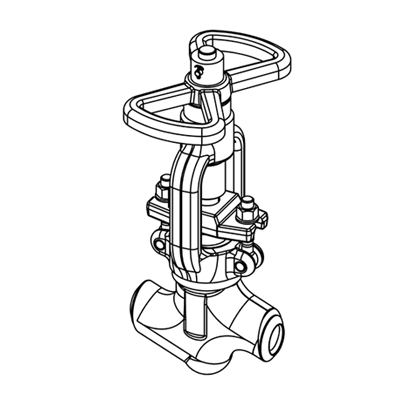

Premium design of stop valves

- Quick-release valve seats;

- Valve stem and seat are made of steel 12Х18Н10Т and reinforced with electrolytic plasma polishing, implantation of nitrogen ions, multilayer ionic and plasma coating with titanium nitride;

- Threaded spindle bush — straight bronze БрОФ10-1 (enhances service life);

- Warranty: 36 months.