Developments

- DEVELOPMENTS

LRV

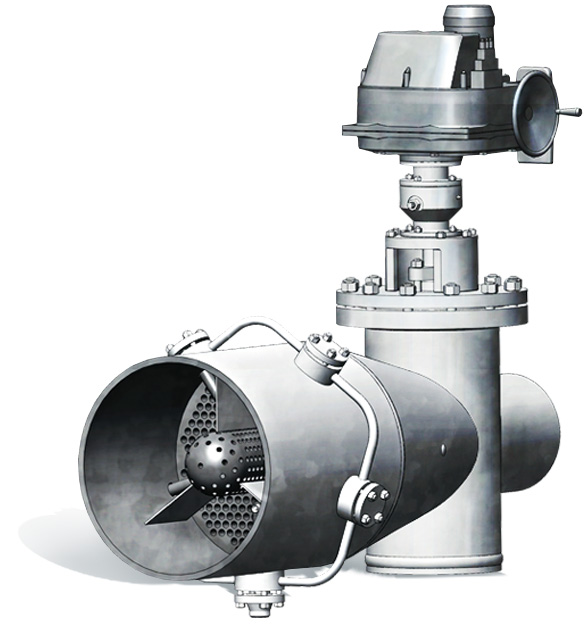

Disk Valve - Block-type pressure-reducing

desuperheating station - Desuperheating station

OP-AMK

Block-type pressure-reducing desuperheating station

This station provides for a blended design and comprises regulating valve, steam desuperheating station and silencer assembly

Advantages compared to conventional PRDS:

Compact design and simple assembly

Cooling water is injected through the axial passage of the valve spindle into steam reduction area. Herewith, intense disintegration of water particles, mixing with steam and fast evaporation occur. Release of cooling water particles outside the valve body is excluded. Temperature is efficiently regulated even al low loads

Auxiliary pressure reduction stages (their number is determined by thermohydraulic calculations) reduce noise and vibration according to health and safety regulations

Upgraded valve spool provides for protection from jams

Top priorities of development of new valve models:

-

Extension of lifetime of the gate valve elements (spindle, spool, disk, seat) by use of plasma building-up welding of the working surfaces. E.g., wire 20Х13 is conventionally used for building-up welding of the sealing surfaces of the valve disk and seat (manufactured by OJSC Sibenergomash). But we use electrodes ЦН-6Л, and such metal is 3 times erosion-resistant than wire 20Х13

-

Transition from the casted bodies to the welded bodies that are different in enhanced metal structure, absence of pockets and shells, less metal consumption

-

Development of full-flow bodies for stop valves

-

Enhanced spraying of cooling water due to steam power; increased number of injectors; nozzles with load-dependent alternating flow characteristics

-

Enhanced ergonomics