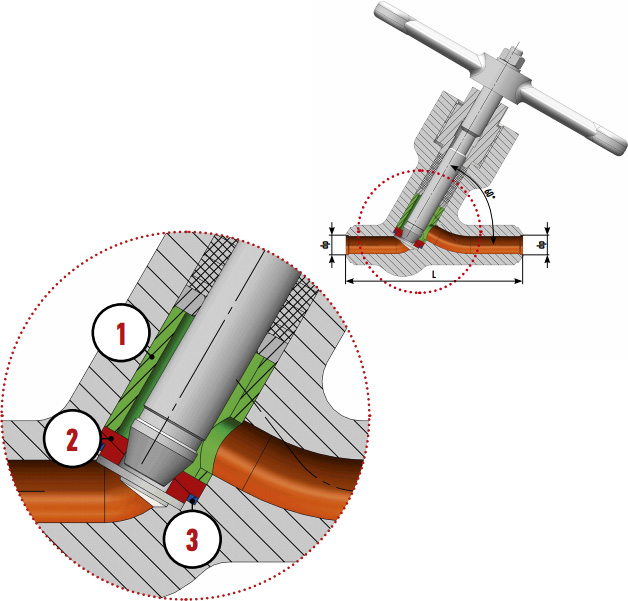

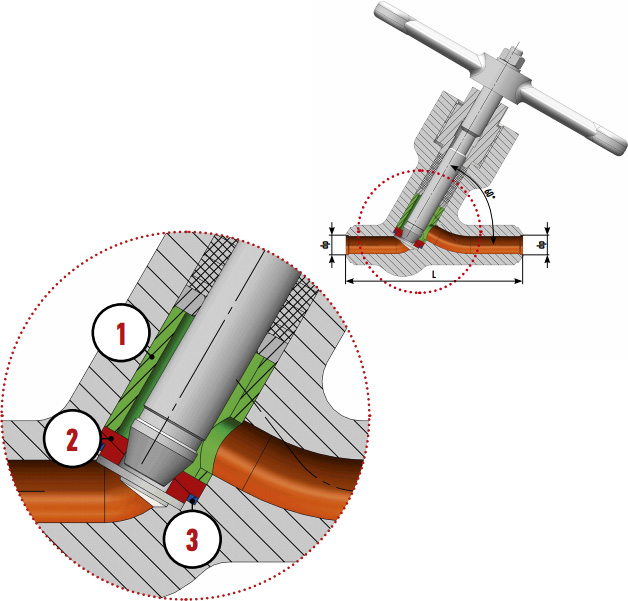

- Steady bush

- Detachable seat

- Sealing gasket

These valves are

designed for complete

cut-off of medium flow.

Bore element has low flow

friction factor.

| Destination | DN, мм. |

PN, MPа |

Т, С° | Class ANSI | ξ | Torque N•м | dp, мм |

L, мм |

Actuator type* | Configuration** | Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

| amk.lvl.10.100.450 | 10 | 10,0 | 450 | 600 | 3.8 | 20 | 10 | 110 | A | М, Г, Э | 3.0 |

Extension of lifetime of the gate valve elements (spindle, spool, disk, seat) by use of plasma building-up welding of the working surfaces. E.g., wire 20Х13 is conventionally used for building-up welding of the sealing surfaces of the valve disk and seat (manufactured by OJSC Sibenergomash). But we use electrodes ЦН-6Л, and such metal is 3 times erosion-resistant than wire 20Х13

Transition from the casted bodies to the welded bodies that are different in enhanced metal structure, absence of pockets and shells, less metal consumption

Development of full-flow bodies for stop valves

Enhanced spraying of cooling water due to steam power; increased number of injectors; nozzles with load-dependent alternating flow characteristics

Enhanced ergonomics

* Имя:

Телефон:

* E-mail:

* Сообщение: