Advantaged of Desuperheating station OP-AMK:

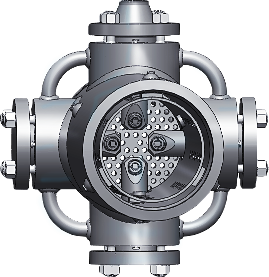

Increase in number of nozzles allow for more efficient spraying and reduction of section length where evaporation of cooling water occurs. Desuperheating station OP-AMK is equipped with 4 nozzles for cooling water injection. Single-side connection to cooling water pipeline makes assembly even easier. Next, injected water is distributed into 4 nozzles. Water is injected perpendicularly to the axis of steam movement; water cloud is generated in the center of the desuperheating station and actively mixes with steam without touching the pipeline walls. Injection through 4 nozzles allows for load reduction in each nozzle compared to 2 or 1 nozzle design. Injected water flow disintegrates into smaller jets, which improves mixing with steam and evaporation of fluid, as well as prevents from release of water particles outside the desuperheating station.